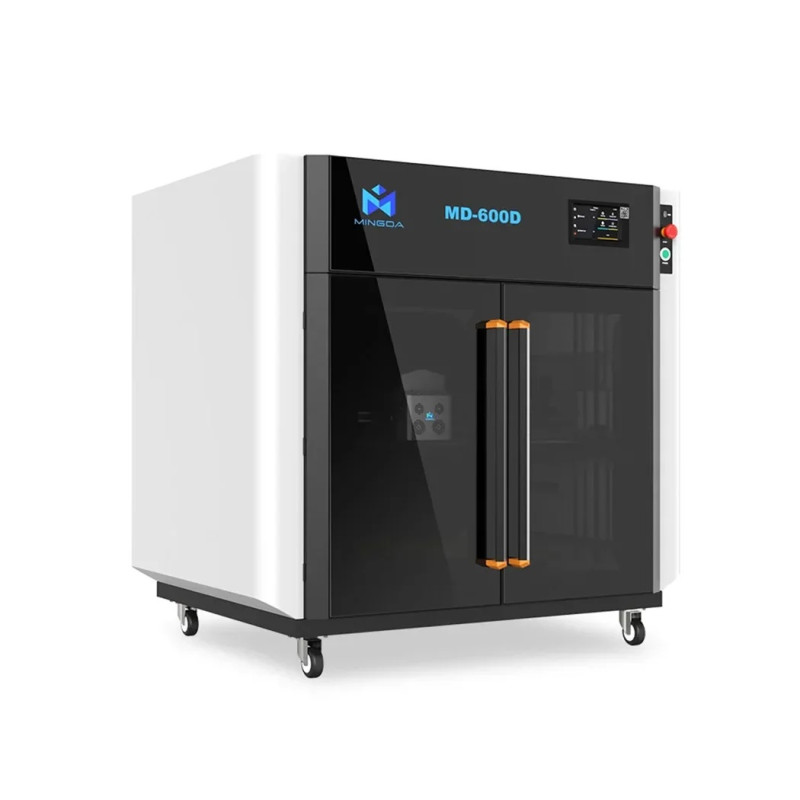

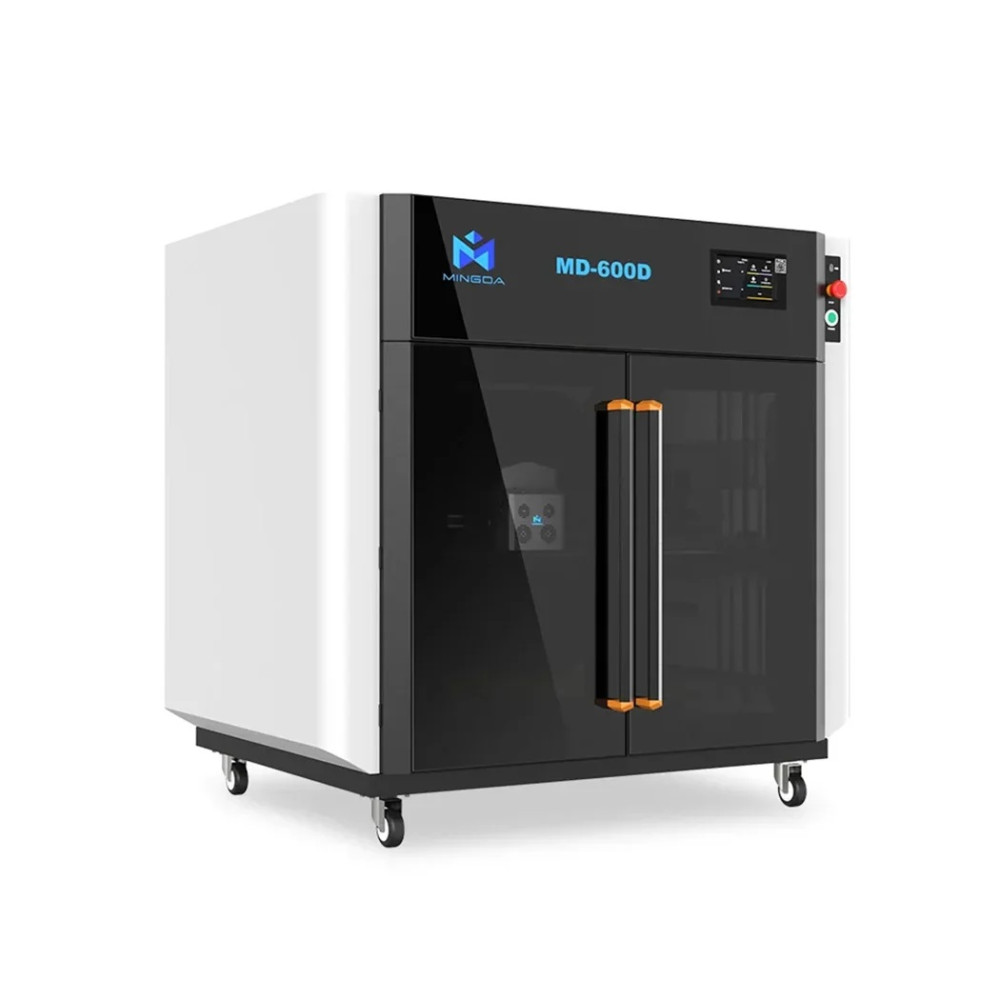

High-Precision 3D Printer for Large, Complex Industrial Components

The MD-600D 3D printer represents a professional solution for demanding printing requirements, offering an impressive build volume of up to 600 mm in cubic form. With a high-temperature dual extruder capable of reaching temperatures up to 350 °C and innovative fast-printing functions, this printer is specifically designed to efficiently and precisely manufacture large industrial parts with complex geometries. Thanks to numerous advanced features and proven processes, the MD-600D is already successfully used in mass production and has established itself as the preferred choice in its size and price range worldwide.

Five Times Faster Printing Speed – A Breakthrough in Printing Efficiency

The MD-600D achieves a printing speed of up to 300 mm/s, with an impressive peak acceleration of 10,000 mm/s². The acceleration occurs in just 0.02 seconds from 0 to 300 mm/s, enabling ultra-efficient printing.

- Travel Speed: 500 mm/s

- Maximum Printing Speed: 300 mm/s

- Maximum Material Flow: 40 mm³/s

Dual Extruder for Precise Printing of Complex Models

The dual-extruder function allows users to print complex structural models with exceptional precision. This feature focuses on the use of high-performance and dissolvable support materials, which are particularly important for models with overhangs. The second extruder enables the printing of support structures with a dissolvable material, facilitating the removal of supports and ensuring a smooth printing experience.

- Ability to print support materials

- Simultaneous printing in two colors

- Support for TPU95A and HtPA-CF while processing TPU and PETG simultaneously

- Compatibility with water-soluble filament

Suitable 3D Printing Materials for Your Applications

With a hotend temperature of up to 350 °C, you can process a variety of engineering materials as well as common filaments. This opens up the possibility of creating high-quality prints with different properties.

- Common Filaments: PLA, TPU, PETG

- Engineering Filaments: HtPA, PET-GF, PET-CF, PA12-CF, HtPA-GF, HtPA-CF, HtPA-GF25, HtPA-CF25, and many more

- Support Materials: S-Mulit, S-HtPA, and other options

These materials enable you to realize demanding projects and optimally meet your printing requirements.

High Precision at Fast Printing Speeds

The use of linear guides and a closed-loop motor design ensures stability and accuracy during the printing process.

Thanks to the closed-loop motors, this printer provides a fast response time without inertia or delay. The closed-loop control solves the problem of step loss, significantly reducing heat and noise generation. This allows for printing models with exceptional precision and speed.

Excellent Stability for Long-Term Printing

- Custom CNC Sheet Integration

This measure ensures the stability of the machine and significantly contributes to its longevity. Robust profiles and high-quality components guarantee sustainable and efficient use. Since the development of MINGDA 3D printers in 2012, these machines have proven to achieve an average of over 35,000 hours of printing time in use, underscoring their exceptional stability.

User-Friendliness at the Highest Level

The MINGDA OrcaSlicer is our proprietary advanced slicing software. All slicing profiles for different materials have been thoroughly tested and validated by our engineers. No adjustments to the parameters are required before printing, allowing you to effortlessly achieve high-quality printing results.

The printer is delivered fully assembled and calibrated to ensure optimal performance. Simply plug it in and start printing immediately without prior knowledge.

- PEI Flexible Print Platform

This platform offers excellent adhesion, high-temperature resistance, and compatibility with various filaments. The printed object can be easily removed by simply bending the platform.

- Automatic Calibration without Manual Intervention

This feature simplifies the printing preparation and ensures precise detection of the first layer.

- Remote Control and Management of Multiple Machines

Once connected via WiFi or a network cable, you can control the MD-600D remotely and monitor the printing process in real-time. Additionally, the printer supports the simultaneous management of multiple machines, enabling efficient mass production.

Automatic Self-Diagnosis on Startup

Upon startup, the machine performs an automatic check of the extruder, heated bed, camera, automatic calibration, fan, and other components. If deviations are detected, a corresponding message appears on the printer's screen to allow for quick and uncomplicated troubleshooting.

Self-Developed Core Hardware by MINGDA

- Fast and Even Performance

The powerful 64-bit motherboard, driven by a 6-core CPU, enables rapid data processing and swift execution of 3D printing tasks. With 32 GB of memory, large files can be quickly saved, exported, and printed.

- Print Continuation and Filament Detection

The printer automatically saves its current position and print data. In the event of a sudden power failure, it lowers the print platform and retracts the filament. After power is restored, printing seamlessly continues from the last position.

If the filament runs low, the printer stops the printing process and issues a warning message to prompt the user to replace the filament, thus avoiding unnecessary print losses.

Large Printing Capacity

- Build Volume: 600 x 600 x 600 mm

- Machine Dimensions: 1300 x 965 x 1255 mm

10-Inch IPS HD Screen

The MD-600D is equipped with a 10-inch IPS HD computer screen. Unlike conventional LCD screens, it offers bright, vibrant, and natural images in high quality from various angles. Additionally, it is more environmentally friendly and energy-efficient.

Product Parameters

- Model: MD-600D

- Printing Technology: FFF - FDM

- Build Volume: 600 * 600 * 600 mm

- Extruder: Dual

- Machine Dimensions: 1300 * 965 * 1255 mm

- Extruder Type: Dual Extruder

- Nozzle Diameter: 0.4 mm (optional nozzles: 0.6, 0.8, 1.0 mm)

- Maximum Extruder Temperature: ≤350°C (recommended temperature ≤320°C)

- Platform Temperature: ≤110°C

- Maximum Material Flow: 40 mm³/s

- Maximum Printing Speed: 500 mm/s (recommended printing speed: 200-300 mm/s)

- Supported Software: MingDa OrcaSlicer, Prusa Slicer, etc.

- Screen: 10-Inch HDMI Touchscreen

- Power Supply: 100/240AC 50/60Hz

- Nominal Power: 2000 W

- Firmware: Klipper

- Filament Compatibility:

- Common Filaments: PLA, TPU, PETG

- Engineering Filaments: PET-C F/GF, HtPA-CF/GF, HtPA-GF25/CF25

- Support Filaments: S-Mulit, S-HtPA, etc.

These specifications highlight the versatility and performance of the MD-600D, making it an excellent choice for professional applications in 3D printing.